IMPLEMENTING ENERGY / EMISSIONS

REDUCTION MEASURES

The Clean Air Charter lists six key areas in which businesses

can make a difference to reduce air pollution. Although many of these reductions may

result in additional business capital and/or operating costs, every business should look

into their business nature, develop a fair, practical and cost-effective air quality

management policy.

7-7-7 Care-for-Air Public

Guideline

The HKGCC and the BCE have developed the "7-7-7 Care-for-Air"

Guideline for the general public to take immediate, practical steps to contribute to improving

air quality at home, at work and while travelling, especially when the Air Pollution Index is

high.

Make That Little Effort at Home

1. Switch off unnecessary domestic appliances - make use of natural light and ventilation.

2. Don't use standby mode - turn off appliances completely when not in use.

3. Set a comfortable room temperature - don't over cool or over heat.

4. Avoid using the tumble drier.

5. Don't use products containing VOCs, e.g. paints, hair and personal care sprays, etc.

6. Reduce direct emissions from cooking, e.g. thaw food in the fridge before cooking, postpone

your BBQ, etc.

7. Don't smoke

Make That Little Extra Effort at Work

1. Activate "sleep" mode in office equipment during office hours, including

photocopiers, scanners and printers.

2. Don't use standby mode after working hours - turn off unnecessary equipment completely

including the computer.

3. Minimize photocopying to reduce ozone emissions.

4. Wear clothing that keeps you comfortable in the office.

5. Make conference calls or use other electronic media to reduce travelling for business

meetings.

6. Adopt flexible working hours to reduce emissions caused by traffic congestion.

7. Use products with zero or low VOCs during renovations.

Make That Little Extra Effort on the Road

1. Reduce unnecessary travel.

2. Use the stairs wherever possible to save energy.

3. Walk or ride a bicycle for short journeys.

4. Use public transport.

5. Plan your travel or carpool to avoid single-passenger car trips.

6. Stop using vehicles that emit black smoke.

7. Don't leave the engine idling |

|

Every Member of Staff Needs to

Contribute

"Every member of

staff should contribute to environmental protection," Mr James Graham, Chief Executive of

Jardine Engineering Corporation (JEC) said. "Therefore, we launched the JEC Clean Air

Campaign Award to mobilise colleagues with information and action to protect the

environment." "Every member of

staff should contribute to environmental protection," Mr James Graham, Chief Executive of

Jardine Engineering Corporation (JEC) said. "Therefore, we launched the JEC Clean Air

Campaign Award to mobilise colleagues with information and action to protect the

environment."

The awards cover three categories, namely Clean Air Technology, Best

Outdoor Clean Air, and Best Indoor Clean Air awards. The Campaign is open to all JEC's 3,000

technical and general employees.

Forbes recently reported that a number of Hong Kong companies were forced

to raise remuneration levels to attract expatriates put off by the air quality in Hong Kong.

Hong Kong's status as the financial capital of Asia can and will be threatened if it loses its

ability to retain key local and foreign executives. A survey conducted by A.C. Nielsen also

showed that most executives knew of someone who had left or was thinking of leaving Hong Kong

because of the deteriorating air quality. Together with buzzing media reports, the entire

business and public community has become concerned with our polluted air.

Mr Graham looked at the issue from a different angle. "We should

take action to protect our air and therefore the health of our people, starting with ourselves

and the actions we can take," he said.

As one of the early signatories of the Clean Air Charter, JEC has pledged

to reduce emissions by giving advice to clients as well as in its own operations on matters

like fuel choices and use, regular maintenance and energy efficiency techniques, cut down on

waste through effective recycling schemes in the office and workplaces, and adopt

energy-efficient practices in daily businesses. To be a responsible corporate citizen, a

number of proactive measures have been taken throughout the company.

"We have implemented an Environmental Management System in the third

quarter of 2006, with the aim of achieving ISO 14001 certification by 2007," Mr Graham

explained. "We encourage the sale of environmentally friendly products - as of July 2006,

more than 39% of our clients purchased diesel generator sets which met the US's EPA Tier 1

Emissions Standards, while a further 6% required that Tier 2 standards were met. JEC also

closely monitors to ensure that ultra low sulphur diesel is used in company's vehicles."

Within the company, JEC

has also taken measures to reduce electricity usage. By way of example, energy saving T5

fluorescent tubes are used in place of conventional tubes, saving an estimated 38.6 MWh of

electricity per year. Lights are switched off whenever possible - lighting at respective zones

in the main office has to be manually turned on, whilst they are switched off by default after

7:45 pm daily. In line with government recommendations, JEC have maintained relative humidity

and indoor air temperature at government recommended levels since August 2006 and regularly

monitors the chilled water that it is using from the building owners in the premises that it

occupies which helps to ensure that energy use is minimised for the cooling of its premises. Within the company, JEC

has also taken measures to reduce electricity usage. By way of example, energy saving T5

fluorescent tubes are used in place of conventional tubes, saving an estimated 38.6 MWh of

electricity per year. Lights are switched off whenever possible - lighting at respective zones

in the main office has to be manually turned on, whilst they are switched off by default after

7:45 pm daily. In line with government recommendations, JEC have maintained relative humidity

and indoor air temperature at government recommended levels since August 2006 and regularly

monitors the chilled water that it is using from the building owners in the premises that it

occupies which helps to ensure that energy use is minimised for the cooling of its premises.

"Apart from the Awards, we ask each of our colleagues and associates

to support the clean air initiative from top management to apprentices in the workplace. JEC

will be reporting on the progress made in its support of the Clean Air Charter at the end of

2006," Mr Graham said. |

|

¡@

Energy Reduction Measures in

Offices

Various

organisations have provided tips that are relevant to reducing energy consumption in

commercial premises in Hong Kong. Below are some examples of practical measures. Various

organisations have provided tips that are relevant to reducing energy consumption in

commercial premises in Hong Kong. Below are some examples of practical measures.

Ventilation and Air Conditioning Systems

¡@

¡@

Energy and emissions reduction measures for ventilation and air

conditioning include:

- Setting the temperature of air-conditioned rooms to a comfortable

temperature;

- Cleaning air-conditioning systems and dust filters regularly;

- Using water-cooled air conditioning systems instead of the air-cooled

type;

- Encouraging staff to wear suitable clothing (e.g. allowing staff not to

wear suits);

- Installing thermometers to monitor the room temperature; and

- Installing carbon dioxide (CO2) sensors to monitor indoor air freshness

and to control the operation of the fresh air intake.

|

| Tips: If the

temperature of an air-conditioned room were set one degree higher, the electricity consumption

would be reduced by 10 percent.

Source: Health, Safety and Environmental Report 2004, Towngas

Website:

|

|

|

Reduce Emissions from

Air-Conditioning

In Hong Kong, power used

for air-conditioning accounts for 1/3 of the total consumption. If the temperature of all

air-conditioned venues is raised by one degree Celsius, we can save more than 300 million

units of electricity a year. This means the population can save $300 million in electricity

tariffs, reduce about 200,000 tonnes of carbon dioxide, 800 tonnes of sulphur dioxide, 400

tonnes of nitrogen oxides and 30 tonnes of respirable suspended particulates annually. In Hong Kong, power used

for air-conditioning accounts for 1/3 of the total consumption. If the temperature of all

air-conditioned venues is raised by one degree Celsius, we can save more than 300 million

units of electricity a year. This means the population can save $300 million in electricity

tariffs, reduce about 200,000 tonnes of carbon dioxide, 800 tonnes of sulphur dioxide, 400

tonnes of nitrogen oxides and 30 tonnes of respirable suspended particulates annually.

Given such high level of energy consumption from air-conditioning,

workplace temperature should be adjusted at a comfortable level but not excessive to encourage

energy conservation and to reduce emissions. Companies should make reference to the relevant

standard recommended by the HKSAR Government, i.e. setting air-conditioning temperature at

25.50C during the summer months.

Source: HKSAR Government |

|

Use of Water-cooled Evaporative

Chiller

In 2004, The Hong Kong and China Gas Company Limited (Towngas) saved over

500,000 kWh at their North Point Headquarters by becoming the first commercial organisation in

Hong Kong to replace air-cooled condensers with water-cooled evaporative chillers. Other

initiatives such as keeping the office temperature between 23-27oC and implementing a chiller

sequencing programme also help to further reduce the electricity consumption.

Source: Health, Safety and Environmental Report 2004,

Towngas Website: www.towngas.com |

|

Office Equipment

Action that you can take to reduce energy consumption or

emissions into the air associated with office equipment include:

- Replacing electrical appliances and office equipment with more

energy-efficient models with an Energy Label (see Appendix C);

- Turning monitors off during lunch hours and at the end of the day, or

when you are away from the workplace;

- Activating the "sleep" mode in office equipment during

office hours for photocopiers, scanners and printers; and

- Turning unnecessary equipment off (including computers).

Think twice before you make copies,

Use energy efficiency equipment

Office equipment, such as photocopiers and laser printers, emit ozone.

Therefore, they should be placed in an area with good ventilation. To reduce emissions, you

are also advised to:

- Think twice before you copy or print ¡Ð how many you need and don't

copy/print too much.

- Avoid fault printing by checking the operation condition and mode setting

before pressing the button.

- Photocopy on both sides of paper and shrink the size of document if

possible.

If you are looking for photocopiers or printers, look for ones that are

recognized as being energy efficient. Products with the ENERGY STAR, for example, meet strict

energy efficiency guidelines set by the US Environmental Protection Agency and US Department

of Energy.

In addition to energy-saving appliances, an emulsion aggregation toner

that uses 35% less energy than conventional toners has been developed, thus minimizing carbon

dioxide emissions.

Source: Fuji Xerox Hong Kong |

|

Lighting

Measures to reduce energy consumption or emissions from

lighting include:

- Replacing conventional fluorescent tubes or light bulbs (e.g.,

T12 or T10 fluorescent tube) with energy efficient models;

- Upgrading existing lighting systems by installing quasi-electronic

ballast (QEB);

- Using shorter fluorescent tubes for over-illuminated areas;

- Reducing the number of fluorescent tube for over-illuminated areas;

- Installing occupancy sensors to control lighting in areas that are

used infrequently, (e.g. conference rooms);

- Making use of daylight whenever possible; and

- Turning lighting off if it is not needed (e.g. during lunchtime

and after work). Place "Save Energy" stickers near the switch as a reminder.

Tips:

- Replacing T12 or T10 fluorescent tubes with T8 tubes can reduce electricity

consumption by about 10%.

- Replacing electromagnetic ballasts in T12, T10 or T8 fittings with

electronic ballasts can reduce about 20-25% electricity consumed.

- Replacing T12, T10 or T8 fluorescent light fittings (with electromagnetic

ballasts) with T5 fluorescent light fittings (with electronic ballasts) can reduce about 30% to

40% electricity consumed.

- Replacing incandescent light bulbs with compact fluorescent lamps (CFL) can

reduce energy consumption by 70%-80%.

- Using shorter tubes can save 30% to 60% on electricity consumption.

- Reducing the number of fluorescent tubes can cut electricity consumption by

about 33%.

Source: EMSD |

|

Case Study: Wing's Trading Co.

Ltd

Wing's Trading Co. Ltd occupies a typical office in Kwun Tong. The first

floor is used as an office and has an area of approximately 7,000 m2. The third floor is used

for storage and as a show room. Office cooling is provided by both a water-cooling tower and

window-mounted or split-type air conditioners.

The company does not make any significant direct emissions into the air

from this site, however, as with all offices, the consumption of energy will contribute

indirectly towards emissions to air from power stations, through the use of energy. Wing's

Trading Co. Ltd has a good understanding of the importance of saving energy and the company is

implementing the following measures to reduce the energy consumption during their operations:

1. During lunchtime, lighting at workstations is turned off and the

"sleep" mode for office equipment is activated.

2. Only authorized persons are permitted to adjust the room temperature.

3. Water-cooling type air conditioning systems are used instead of air-cooling type systems.

4. Energy-saving light bulbs are used in the pantry.

5. Air-conditioners in the pantry are switched off outside the lunch hour and fans are used

instead for ventilation.

6. Only a limited number of light bulbs are switched on in the pantry outside the lunch hour

to minimize the energy usage.

7. Air-conditioners and the light are switched off in meeting rooms when these are not in use.

The above measures are general and can be applied to all offices |

|

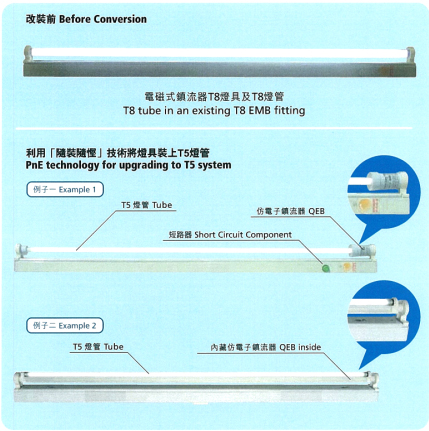

Upgrading T8 tubes to the T5

system with a Quasi-Electronic Ballast (QEB)

For upgrading lighting to the T5 system, a T8 tube can be replaced with a

T5 tube together with a Quasi-electronic Ballast (QEB) attached as an end cap or inside a

fitting.

The energy savings and payback period for a real example are shown below:

From |

To |

Energy Savings (%) |

Payback Period (Yrs) |

Resulting Lighting Level

(compared to existing lighting level) (%) |

1200 mm T8 (Electromagnetic ballast (EMB) ) |

T5 system with (Quasi Electronic Ballast) |

33 |

3.5 |

118 |

3 x 1200 mm T8 (EMB) |

2 x T5 with Redirection |

56 |

1.8 |

89 |

Source: Retrofit with Energy Efficient Fluorescent Lighting System:www.emsd.gov.hk |

|

¡@

Energy / Emissions Reduction Measures in the Street

and at Work

Vehicle Movement / Idling

Hybrid Vehicles

Hybrid vehicles are more

environmentally friendly than conventional vehicles and these types of vehicles are available

on the Hong Kong market now. The technology uses a combination of a petrol engine and an

electric motor drive to improve fuel efficiency and reduce emissions. Typical fuel consumption

and emissions from hybrid vehicles are about 50% below equivalent, conventionally powered

vehicles. Hybrid vehicles are more

environmentally friendly than conventional vehicles and these types of vehicles are available

on the Hong Kong market now. The technology uses a combination of a petrol engine and an

electric motor drive to improve fuel efficiency and reduce emissions. Typical fuel consumption

and emissions from hybrid vehicles are about 50% below equivalent, conventionally powered

vehicles.

In the Policy Address 2006 announced on 11 October 2006, the HKSAR Chief

Executive, Mr Donald Tsang proposed that a 30% reduction in first registration tax will be

given to people purchasing vehicles with low emissions and high fuel efficiency (environmental

friendly vehicle, such as hybrid vehicles), subject to a ceiling of $50,000 per vehicle. |

|

Cleaning the Air in the Streets

In our busy streets, air pollution is mainly caused by motor vehicles,

particularly diesel vehicles, such as trucks, buses and light buses. Pollutants such as

particulates and nitrogen oxides are often trapped between the tall buildings that line the

streets.

Obviously we need more green vehicles on the streets, especially on busy

corridors. And there are practicable measures to reduce pollution from vehicles, as

demonstrated by KMB.

As one of the largest public transport companies in Hong Kong, KMB makes

around 2.8 million passenger trips daily. Among the 4,053 buses in the KMB bus fleet, 3,450

buses achieve Euro II or above emissions standards, with 448 and 567 buses achieving Euro III

and close to Euro IV emissions standards respectively. In early 2006, KMB took the lead to

introduce two Euro IV double deck buses to Hong Kong. With the most advanced technology in

environmental protection, the Euro IV engine reduces emissions of nitrogen oxides and

particulates by 30% and 80% respectively when compared with the Euro III engine.

Since 2001, KMB has used ultra-low sulphur diesel (ULSD) in its entire

fleet, significantly reducing exhaust emissions levels of sulphur oxides, nitrogen oxides and

particulates. Catalytic converters have been installed on all KMB buses with pre-Euro or Euro

I engines. With the catalytic converters and the use of ULSD, the exhaust emissions of

pre-Euro or Euro I buses have been improved to Euro I and II engine standards respectively.

Buses equipped with Continuous Regeneration Traps (CRTs) can achieve a

significant reduction in particulate matters and reduce smoke levels to virtually zero. Euro

III-engined buses equipped with CRTs plus an exhaust gas recirculation device are able to meet

emissions standards at a level close to Euro IV engine standards.

Recently, KMB has also upgraded its Traffic Operations Management System

for more efficient deployment of its "Euro buses". KMB notes the emissions standards

for all its buses and screens the database for all bus routes requiring emissions standards at

Euro II or above. Whenever there is an ad-hoc bus arrangement calling for replacement of any

bus running on a busy corridor, the system will alert staff in the event of any mismatch

involving a non-Euro II or above bus, thus guaranteeing that they select the appropriate bus

type.

Currently, all KMB buses running on Yee Wo Street, and 90% of KMB buses

operating on Hennessy Road, Queensway, Des Voeux Road Central and Nathan Road, are at Euro II

or above standard.

|

|

Machinery and Equipment

Measures can be

employed to reduce energy consumption from machinery and equipment include: Measures can be

employed to reduce energy consumption from machinery and equipment include:

- Installing energy-efficient motors.

- Not using oversized motors, which are inefficient when running at part

load (e.g., 85% load);

- Lubricating motors and drive bearings frequently to avoid overheating

and power loss;

- Adhering to the maintenance schedules recommended by manufacturers;

- Cleaning heating coils in electric boilers regularly; and

- Reducing the number of lifts or escalators in service after

normal working hours and on holidays.

Reducing Energy for

Lifts/Escalators

Hong Kong is densely populated with a high density of high-rise

commercial and residential buildings. Therefore, lifts are essential for almost every

building.

As lifts are used

frequently, they are one of the facilities that consume the most energy in a building. To save

energy, property management companies can switch some lifts to standby mode after office hours

or during off-peak hours to reduce the number of lifts in use. Aging lifts can be upgraded

through a modernization plan to install a state-of-art Variable Voltage Variable Frequency

(VVVF) system, so that lifts are driven by microcomputer rather than traditional mechanical

controls. The smoother acceleration and deceleration that the AC machines produce, and a

slower speed for short distance also reduce energy consumption. In addition, lighting and

ventilation systems can be automatically turned off through refit when the lifts are not in

use. As lifts are used

frequently, they are one of the facilities that consume the most energy in a building. To save

energy, property management companies can switch some lifts to standby mode after office hours

or during off-peak hours to reduce the number of lifts in use. Aging lifts can be upgraded

through a modernization plan to install a state-of-art Variable Voltage Variable Frequency

(VVVF) system, so that lifts are driven by microcomputer rather than traditional mechanical

controls. The smoother acceleration and deceleration that the AC machines produce, and a

slower speed for short distance also reduce energy consumption. In addition, lighting and

ventilation systems can be automatically turned off through refit when the lifts are not in

use.

For escalators, a sensor can be fitted, so that they can automatically

stop when not in use to conserve energy.

Source: Chevalier International Holdings Ltd |

|

VOC Control

The following practices can reduce VOC emissions:

- Avoiding use of aerosol consumer products such as hairspray, air

freshener, deodorants, and insecticides which often use VOCs as their propellants.

Non-aerosol consumer products are usually in pump, solid, liquid, gel, or roll-on forms;

- Avoiding use of solvent-based paints by selecting water-based paints

as alternatives. If solvent-based products cannot be avoided, applying them with hand

brushes or rollers instead of spray systems to reduce the use of thinners, which will also

minimize overspray and wastage;

- Avoiding use of VOC-containing products such as organic cleaning

solvents;

- Selecting "zero-VOC"/"non-VOC" products or those

with a green label (e.g. awarded by the Green Council); and

- Storing VOC-containing products in air-tight containers;

VOC Reduction by Using Soy-based

Ink in the Printing Industry

The US Environmental Protection Agency (EPA) launched a Waste Reduction

and Innovative Technology Evaluation project, focused on the use of soy-based inks as a

substitute for petroleum based inks in printers. Soy-based inks are produced from renewable

resources and emit lower amounts of VOCs during the printing process. Results have shown that

approximately 17% more petroleum-based inks were used on a per sheet printed basis.

Significantly less volatile components were found in the soy-based inks (0.8%) than in the

petroleum-based inks (4.6%).

Green Pagoda Printing Co. Ltd, a 40-year-old printing company, has

replaced traditional ink with soy offset ink in some printing products. Though the cost of

using soy offset ink is slightly higher than that that of traditional ink, the printing

quality associated with soy offset is better, particularly where more than four colours are

required. |

|

¡@

Energy/Emissions Reduction Measures in General

Production-type Businesses

There are some simple procedures that can help reduce emissions from

production-type businesses. These include:

- Checking, cleaning and maintaining exhaust pipes regularly to avoid

the accumulation of dust (which increase the energy efficiency of the system);

- Estimating emissions based on fuel consumption to monitor performance

and to identify improvements;

- Monitoring air pollution control equipment regularly to ensure that

the efficiency with which pollutants are removed is kept at the designated level; and

- Installing suitable emissions control measures as described as

below.

Air Control Measures

Wet scrubbers, adsorption by activated carbon, electrostatic

precipitators, cyclones and fabric filters are the most common air pollution control

equipment used to treat flue gas from emissions stacks. Different emissions control

technologies and their applications are summarized below.

| Emissions Control Technology |

SO2 |

NOx |

PM |

VOCs |

| Wet Scrubber |

|

|

|

|

| Adsorption by activated carbon |

|

|

|

|

| Electrostatic precipitator |

|

|

|

|

| Cyclone |

|

|

|

|

| Fabric filter |

|

|

|

|

Wet Scrubber Wet Scrubber

Wet scrubbing systems can be used to control sticky emissions that

would plug filter-type collectors. This type of pollution control equipment is used to

control both particulate and gaseous emissions simultaneously, to control

acidic/alkaline/odorous gases, to recover soluble dusts and powders.

¡@

¡@

Adsorption

Using Activated Carbon Adsorption

Using Activated Carbon

Adsorption means the attachment of molecules to the surface of a

solid. Adsorbed materials are attached onto the surface of a material, like dust on a

wall. Adsorption is mostly used to remove VOCs. Activated carbon is the most common

adsorbent which is low-cost and can be regenerated.

¡@

¡@

Electrostatic

Precipitator (ESP) Electrostatic

Precipitator (ESP)

Electrostatic Precipitators (ESPs) are used to remove particulates

from flue gases. Particles are given an electric charge by forcing them to pass through a

corona (a region in which gaseous ions flow). The electrical field that forces the charged

particles to the walls comes from electrodes maintained at high voltage in the centre of

the flow lane. Once particles are collected on the plates, they must be removed from the

plates without re-entraining them into the gas stream.

Cyclone

Cyclones

provide a low-cost, low-maintenance method for removing particulates from gas streams. The

general principle of a cyclone system is that the particulate-laden gas is forced to

change direction. As the gas changes direction, the inertia of the particles causes them

to continue in the original direction and be separated from the gas stream. Cyclones

provide a low-cost, low-maintenance method for removing particulates from gas streams. The

general principle of a cyclone system is that the particulate-laden gas is forced to

change direction. As the gas changes direction, the inertia of the particles causes them

to continue in the original direction and be separated from the gas stream.

Multiple cyclones have overall mass removal efficiencies of 70 - 90%.

However, cyclone collection efficiencies fall off rapidly with particle size, so that

control of fine particulates is limited.

¡@

Fabric Filter Fabric Filter

Fabric filter collectors (baghouses) are another technology

used for the removal of particulate matter. The technology is conceptually simple: by

passing flue gas through a tightly woven fabric, particulates in the flue gas will be

collected by the fabric by sieving and other mechanisms. Baghouses are capable removing

98% to over 99.9% of particulates.

¡@

Cost-effective Measures for

Cooling Air at Spunbond Nonwoven (S.Z.) Co. Ltd's Processing Workshop

Spunbond Nonwoven (S.Z.)

Co. Ltd is a non-woven cloth manufacturing factory. The total site area is about 14,500 m2.

Poly-propylene (PP) is the main raw material to manufacture non-woven cloth. PP is melted and

then bonded as a cloth (this technology is called 'Spunbond'). Heaters are used in the process

and mechanical ventilation fans are provided in the processing workshop. However, the

temperature inside the processing workshop is still high due to the heat release from the

melter. Spunbond Nonwoven (S.Z.)

Co. Ltd is a non-woven cloth manufacturing factory. The total site area is about 14,500 m2.

Poly-propylene (PP) is the main raw material to manufacture non-woven cloth. PP is melted and

then bonded as a cloth (this technology is called 'Spunbond'). Heaters are used in the process

and mechanical ventilation fans are provided in the processing workshop. However, the

temperature inside the processing workshop is still high due to the heat release from the

melter.

In order to reduce the indoor air temperature at the processing workshop,

Spunbond Nonwoven (S.Z.) Co. Ltd uses a cost-effective and innovative measure called a

"Water Cooled Screen" to reduce the indoor air temperature. The double layer

water-cooled screen is installed on the windows. A water pipe with sprinklers is installed at

the top of the screen. The water is sprayed onto the screen at the top and is collected in a

sump at the bottom, to be recirculated. Air passing through this screen is cooled by about 3-5

¢XC. |

|

Without a sustainable

environment, we won't be able to produce quality shirts

"Every year we produce 60 million shirts, made from pure cotton. Raw

materials are provided by our cotton farm in Xinjiang." Mr Calvin Tsang of General

Manager of Site Management and Administrative Services of Esquel Group's production base in

Gaoming, said. "The quality of cotton we cultivate is critical to our business."

For this reason, environmental protection has been one of the key

management philosophies of Esquel and the Group has made major efforts to reduce the

environmental footprint of its operations throughout the world.

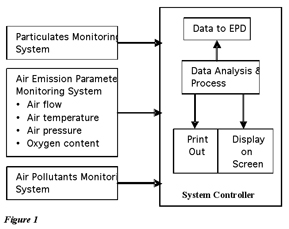

To ensure reliability of

electricity and steam supply as well as increase energy efficiency for such a high annual

production, Esquel has built its own coal-fired power plant near the production base. Emission

control measures including electrostatic precipitator (ESP) and flue gas desulphurization

(FGD) are implemented at the plant to reduce emissions of sulphur dioxide (SO2) and

particulate matter (PM). In addition, air emissions from the power plant are monitored with a

continuous emission monitoring system (CEMS). Real-time data including air pollutant

concentrations, air flow parameters such as oxygen content, temperature, flowrate and pressure

are obtained and stored in a database, which is also sent to the local authorities regularly

for record. To ensure reliability of

electricity and steam supply as well as increase energy efficiency for such a high annual

production, Esquel has built its own coal-fired power plant near the production base. Emission

control measures including electrostatic precipitator (ESP) and flue gas desulphurization

(FGD) are implemented at the plant to reduce emissions of sulphur dioxide (SO2) and

particulate matter (PM). In addition, air emissions from the power plant are monitored with a

continuous emission monitoring system (CEMS). Real-time data including air pollutant

concentrations, air flow parameters such as oxygen content, temperature, flowrate and pressure

are obtained and stored in a database, which is also sent to the local authorities regularly

for record.

¡@

Apart from power

generation emission, production of textiles usually releases fine fibres and cotton dust,

which become suspended in the air. A cyclone is a typical, commonly used and effective means

for removing dust from such processes with removal efficiencies reaching 80%. Apart from power

generation emission, production of textiles usually releases fine fibres and cotton dust,

which become suspended in the air. A cyclone is a typical, commonly used and effective means

for removing dust from such processes with removal efficiencies reaching 80%.

"The textiles industry employs more people around the world than any

other. The companies that make up the industry therefore have much to contribute to social and

environmental responsibility," Mr Tsang said.

At Esquel's factory, an air extraction system is provided in each

workshop to collect the fugitive cotton dust or fibres. The collected air is passed through

cyclone before being discharged into the atmosphere. Water containing cotton and fibres from

the cyclone is sent to Esquel's wastewater treatment plant for treatment and the treated water

is reused in the scrubbers. |

|

Download this Chapter (In PDF Format) Download this Chapter (In PDF Format)

|