UNDERSTANDING YOUR COMPANY

¡@

Before establishing

reduction targets or developing an implementation programme, it is important to understand

your company's air emissions and energy consumption. This Section provides guidance and

references on how to evaluate their company's air emissions and energy consumption and how

to conduct an initial audit of operations. Before establishing

reduction targets or developing an implementation programme, it is important to understand

your company's air emissions and energy consumption. This Section provides guidance and

references on how to evaluate their company's air emissions and energy consumption and how

to conduct an initial audit of operations.

¡@

Quantifying Your Energy

Consumption

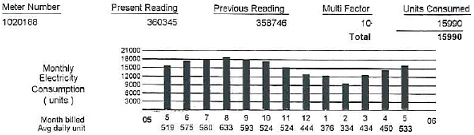

Saving energy reduces air emissions. Electricity and fuel consumption

can be used to quantify energy consumption. This information can be gathered from your

utility and fuels bills. If this information is not routinely kept, establishing a system

to do so is an important first step in quantifying your energy consumption.

1 unit of electricity consumed is equal to 1 kilowatt hour (kWh) and

1 unit of gas consumed is equal to 48 megajoules (MJ) for Towngas or 46 MJ for liquefied

petroleum gas (LPG). These conversion factors are useful for quantifying energy

consumption on a common basis across different sectors and estimating corresponding direct

and indirect air emissions.

¡@

Quantifying Your Air Emissions

Industrial

operations, vehicles and power plants are the main "direct" air pollution

sources in the PRD region. Offices are also an "indirect" air pollution source

as the electricity consumed by these operations results in air emissions from power

plants. Industrial

operations, vehicles and power plants are the main "direct" air pollution

sources in the PRD region. Offices are also an "indirect" air pollution source

as the electricity consumed by these operations results in air emissions from power

plants.

Sulphur dioxide (SO2), nitrogen oxides (NOx),

particulate matter (PM) and volatile organic compounds (VOCs) are key air pollutants in

the PRD region. The Hong Kong Special Administrative Region Government (the HKSAR

Government) and the Guangdong Provincial Government reached a consensus in April 2002 to

reduce emissions of SO2, NOx, PM and VOCs by 40%, 20%, 55% and 55%,

respectively, by 2010, using the emissions levels at 1997 as a base. Therefore, this

sections focuses on quantifying SO2, NOx, PM and VOCs emissions.

Selective key air pollutant emissions sources are summarized

below.

| Emissions Sources |

Air Pollutants |

Sulphur

Dioxide(SO2) |

Nitrogen

Oxides(NOx) |

Particulate

Matter(PM) |

Volatile Organic

Compounds(VOCs) |

Fuel Consumption |

|

|

|

|

Coal and

Oil-fired Power plants Coal and

Oil-fired Power plants |

|

|

|

|

Diesel

oil-fired Generators, Boilers and Furnaces Diesel

oil-fired Generators, Boilers and Furnaces |

|

|

|

|

Vehicles |

|

|

|

|

Motor

vehicles Motor

vehicles |

|

|

|

|

Marine

vessels Marine

vessels |

|

|

|

|

Petrol

filling stations Petrol

filling stations |

|

|

|

|

| Emissions Sources |

Air Pollutants |

Sulphur

Dioxide(SO2) |

Nitrogen

Oxides(NOx) |

Particulate

Matter(PM) |

Volatile Organic

Compounds(VOCs) |

Typical Manufacturing Industries (emissions from processes) (a) |

|

|

|

|

Cement Cement |

|

|

|

|

Chemical Chemical |

|

|

|

|

Construction Construction |

|

|

|

|

Electronics Electronics |

|

|

|

|

Plastics Plastics |

|

|

|

|

Printing Printing |

|

|

|

|

Textiles Textiles |

|

|

|

|

Toys Toys |

|

|

|

|

Indirect Source |

|

|

|

|

Office Office |

(c) (c)

|

(c) (c)

|

(c)(d) (c)(d)

|

(e) (e)

|

Notes:

(a) Many different industries operate in HK and the PRD region, these are just some of the

more common industry sectors.

(b) Motor vehicle fuel sold in Hong Kong has a low sulphur content. Much of the diesel

sold on the Mainland does not.

(c) NOx and SO2 emissions are generated from energy consumed in

offices.

(d) PM emissions in offices also include dusts from ventilation systems, paper,

photocopiers, printers, etc.

(e) VOCs in offices come from cleaning agents, chemical usage, paints, furnishing, etc.

Emissions Estimated from Energy Consumption

Electricity, towngas or liquefied petroleum gas (LPG) are the common

sources of energy used in Hong Kong. "Indirect" air emissions from offices can

be estimated by considering the quantity of electricity consumed, as identified from

monthly electricity bills, and using typical emissions factors.

Electricity

Nitrogen oxides (NOx), sulphur dioxide (SO2)

and particulate matter (PM) are the major air pollutants generated from power stations. A

reduction in electricity used will reduce air emissions from power stations. To estimate

indirect emissions from electricity usage in Hong Kong the following equations can be

used.

EMISSIONS ESTIMATION FROM USE OF

HONG KONG ELECTRICITY

NOx = electricity used (no. of units**) x 1.3 (g/kWh)

SO2 = electricity used (no. of units**) x 2.1 (g/kWh)

PM = electricity used (no. of units**) x 0.1 (g/kWh)

** 1 unit (in the electricity bill) = 1 kWh

Reference to CLP Social and Environmental Report 2005 and HEC Environment, Quality, Health and

Safety Report 2005 |

|

EXAMPLE OF EMISSIONS ESTIMATIONE

missions estimation from electricity bill from the office of "ABC" in Hong Kong.

NOx = 15,990 x 1.3 (g/kWh) = 21 kg

SO2 = 15,990 x 2.1 (g/kWh) = 34 kg

PM = 15,990 x 0.1 (g/kWh) = 1.6 kg

** 1 unit (in the electricity bill) = 1 kWh

Reference to CLP Social and Environmental Report 2005 and HEC Environment, Quality, Health and

Safety Report 2005 |

|

EMISSIONS ESTIMATION FROM GASEOUS

FUEL CONSUMPTION

NOx = no. of unit x 48 (MJ) x 8.92 (kg/106 MJ of gas) [Towngas] [Towngas]

NOx = no. of unit x 46 (MJ) x 8.92 (kg/106 MJ of gas) [LPG] [LPG]

Reference to Towngas Environment, Quality, Health and Safety Report 2005 |

|

¡@

Emissions Estimated from Vehicle Movement / Idling

NOx and PM

are the main air pollutants generated from vehicle movements on roads and idling.

Different sizes and types of vehicle engines produce different levels of air pollutants.

Estimating air emissions from vehicle fleets is complex and would require more detailed

information on the vehicle type, engine condition, fuel used, running pattern, and etc. To

provide a simple way, total distance travelled and idling time can be used to conduct

rough estimations of vehicle emissions. NOx and PM

are the main air pollutants generated from vehicle movements on roads and idling.

Different sizes and types of vehicle engines produce different levels of air pollutants.

Estimating air emissions from vehicle fleets is complex and would require more detailed

information on the vehicle type, engine condition, fuel used, running pattern, and etc. To

provide a simple way, total distance travelled and idling time can be used to conduct

rough estimations of vehicle emissions.

The HKSAR Environmental Protection Department (EPD) has

developed a comprehensive EMFAC model to estimate vehicle emissions. Further information

on the EMFAC model can be found at EPD's Website.

(www.epd.gov.hk/epd/english/environmentinhk/air/guide_ref/emfac.html).

EMISSIONS ESTIMATION FROM VEHICLE

MOVEMENT / IDLING

While Travelling

Air Emissions = [kilometres travelled] x [average emissions for different vehicle type (g/km)]

| Air Pollutant |

NOx |

PM |

| Average Fleet Vehicle Emissions (g/km travelled) |

|

|

| Passenger car |

0.9 |

0 |

| Light Goods Vehicles |

1.6 |

0.3 |

| Heavy Goods Vehicle |

8.2 |

0.6 |

Reference to Energy Consumption Indicators (HKSAR Electrical and Mechanical

Services Department), Traffic Census 2005 (HKSAR Transport Department), and Emissions

Inventory Guidebook 2005 (European Environment Agency)

Example:

A light goods vehicle running 20 km a day,

NOx emissions = 20 x 1.6 = 32 g ; PM emissions = 20 x 0.3 = 6 g

While Idling

Air Emissions = [Idling time (min)] x [average emissions for different vehicle type (g/min)]

| Air Pollutant |

NOx |

PM |

| Average Emissions (g/min of idling) |

|

|

| Passenger car |

0.2 |

Negligible |

| Public Light Bus / Passenger Van /Light Goods Vehicles |

0.5 |

0.05 |

| Heavy Goods Vehicle / Non-franchised / Franchised Bus |

2.0 |

0.05 |

Example:

A heavy goods vehicle idling to unload goods for 10 minutes,

NOx emissions = 10 min x 2.0 g/min = 20 g ; PM emissions = 10 min x 0.05 g/min = 0.5 g |

|

¡@

Emissions Estimation from Industrial Operations

Power plants

and industrial operations contribute to the local air pollution problem in Hong Kong and

the PRD. Industrial processes produce a variety of different air pollutants and back-up

diesel generators also contribute. Power plants

and industrial operations contribute to the local air pollution problem in Hong Kong and

the PRD. Industrial processes produce a variety of different air pollutants and back-up

diesel generators also contribute.

Emissions from Power Plants in PRD Region

Emissions from power plant operating in Hong Kong have been discussed

in the above section. In the PRD region, there are a large number of government and

privately owned power plants operating. As noted above, NOx, SO2 and

PM are the main air pollutants from these power plants.

In China, power plants are mostly coal-fired. The emissions levels of

SO2 from power plants depend in part on the sulphur content of the

coal used as well as the nature and type of emissions controls installed, which can vary

significantly between power plants. The following equations can be used to estimate

pollutant emissions from electricity consumed in the PRD.

EMISSIONS ESTIMATION FROM

ELECTRICITY IN MAINLAND CHINA

NOx = electricity used (kWh) x 1.4 (g/kWh)

SO2 = electricity used (kWh) x 2.1 (g/kWh)

PM = electricity used (kWh) x 0.2 (g/kWh)

Reference to Study of Air Quality in the Pearl River Delta Region,

Environmental Protection Department |

|

¡@

Emissions from Diesel Backup Generators

Diesel generators are usually used as backup for power

generation in manufacturing industries. Air pollutants will be generated from the

combustion of diesel oil and NOx is the main air pollutant. The emissions of NOx can be

estimated based on the installed capacity of the generator and an emissions factor. The

following simplified formula could be useful for estimating NOx emissions.

EMISSIONS ESTIMATION FROM DIESEL

BACKUP GENERATOR

NOx = installed generator capacity (hp) x 0.014 (kg/hp-hr)

x operating hour (hr)

Source : Compilation of Air Pollutant Emissions Factors, AP-42, 5th Edition |

|

¡@

Emissions from Diesel Boiler

Diesel boilers are usually used to provide heat and steam for

the manufacturing processes such as dyeing. NOx and SO2 are the main

air pollutants generated from the combustion of diesel oil. The emissions of NOx and SO2 can be estimated based on the diesel oil consumption, sulphur content in

diesel oil and the well-established emissions factors. The following simplified formula

could be useful for estimating NOx and SO2 emissions.

EMISSIONS ESTIMATION FROM DIESEL

BOILER

If power rating < 293 kW

NOx = diesel oil consumption (litre) x 2.2 g/litre

SO2 = diesel oil consumption (litre) x 17 g/litre x sulphur content in

diesel oil (%)

Source : Compilation of Air Pollutant Emissions Factors, AP-42, 5th Edition |

|

¡@

Emissions from Industrial Process

Different

types of industrial processes will produce different types of air emissions. The US EPA

developed a Compilation of Air Pollutant Emissions Factors, AP-42, 5th Edition (AP-42) in

1995 which is a comprehensive guidebook to assist facility operators to understand: Different

types of industrial processes will produce different types of air emissions. The US EPA

developed a Compilation of Air Pollutant Emissions Factors, AP-42, 5th Edition (AP-42) in

1995 which is a comprehensive guidebook to assist facility operators to understand:

- The types of air pollutants generated by specific activities;

- Methodologies for estimating emissions factors; and

- Suitable air pollution control measures and associated removal

efficiencies.

The AP-42 covers a number of industrial activities including:

- External combustion sources such as boilers;

- Solid waste disposal such as landfill;

- Stationary internal combustion sources such as gas turbine engines;

- Evaporation loss sources;

- Petroleum industry;

- Organic chemical process industries;

- Liquid storage tanks;

- Inorganic chemical industries;

- Food and agricultural industries;

- Wood products industries;

- Mineral products industries such as concrete batching and stone

crushing;

- Metallurgical industries such as aluminium manufacturing.

For further details: www.epa.gov/ttn/chief/ap42/

¡@

Volatile Organic Compounds (VOCs) Estimation

VOCs are a family of

chemical compounds that possess high vapour pressure and low water solubility. Many VOCs

are human-made and are used in the manufacturing of paints, inks, adhesives,

pharmaceuticals and refrigerants. VOCs are a family of

chemical compounds that possess high vapour pressure and low water solubility. Many VOCs

are human-made and are used in the manufacturing of paints, inks, adhesives,

pharmaceuticals and refrigerants.

A "Joint Study on Pearl River Delta Region Air Quality"

completed in 2002 identified paints, the printing industry, VOC-containing consumer

products and motor vehicles to be the major VOC emissions sources in the PRD. VOCs are

mainly emitted from the solvent evaporation and the level of VOC emissions depends on the

composition of the products and solvent. For example, VOC emissions will be higher from

solvent-based paint or printing inks than their water-based equivalents.

The HKSAR Government proposed in late 2004 a scheme to require

mandatory registration and labelling of the VOCs in paints, printing inks and selected

consumer products for sale in Hong Kong. However after extensive consultation, the

Government has amended the initial proposal to be a more direct and effective control

scheme.

In the 2006 Policy Address on 11 October 2006 the HKSAR Chief

Executive, Mr Donald Tsang, announced that legislation to restrict the VOC content of

printing materials, paints and consumer products will be introduced, based on stringent US

and California standards. The new regulation will impose maximum limits on the VOC content

of selected products in phases from 1 April 2007. This will enhance significant reduction

of VOC emissions. During the transitional periods, paints not complying with the future

VOC limits will be required to carry a bilingual advisory label.

¡@

Conducting Initial Audit

Before defining the EEM objective and establishing the reduction

target, you should know the current position of your company, i.e., how much energy is

consumed and how many emissions are produced by your operation. Carrying out an initial

energy and emissions audit is essential to gather the background data of the company.

The types of data to be gathered should include:

| General Information |

- No. of staff;

- Working hours; and

- Floor area.

|

| Information related to air emissions |

- Number of operating stacks

- Types of fuel used (i.e., diesel, natural gas, LPG, etc)

- Monthly fuel consumption rate (litre/month or m3/month)

- Operating hours of each stack

- Any air control measures (i.e., air filter, wet scrubber, cyclone, activated carbon, etc)

|

| Information related to energy consumption |

- Number and types of office equipment (i.e., printers, computers, photocopiers, fax

machines, etc)

- Power rating of industrial equipment (kilowatts, horsepower, etc)

- Operating hours of each equipment

- Type and number of fluorescent tubes / light bulbs

- Electricity bills for the past twelve months

- Gas bills for the past twelve months

- Number of air conditioning units

- What type of air conditioning system (i.e., window-mounted type, split type, water-cooling

tower, etc)

|

| Information related to vehicular emissions |

- Total number of company cars and trucks by type and size of vehicle

- Total kilometres travelled by cars and trucks by type and size of vehicle

|

The gathered data can be used to estimate the energy consumption and

air emissions based on the equations and references presented above. In addition, the

benchmarking system of the HKSAR Electrical and Mechanical Services Department (EMSD), as

described in the next Section, also provides guidance on how to estimate energy

consumption.

The initial audit should be carried out by the EEM Team. The

gathered data should be recorded and kept on file to enable tracking of performance. A

sample template for undertaking an initial audit can be found in Appendix A.

Energy Audit - An Effective

Energy Management Tool

"To many SMEs,

energy audit sounds like a technical term, but it is simply an examination of energy consuming

systems and housekeeping practices to ensure that energy is being used efficiently," Mr

Eddie Wu, Energy Services Manager of CLP Power Hong Kong said. "You can always find room

for improving energy efficiency. Just walk around your office or premises and perform a site

survey following the Energy Audit Guidelines, which is available from various sources such as

the Government's Website." "To many SMEs,

energy audit sounds like a technical term, but it is simply an examination of energy consuming

systems and housekeeping practices to ensure that energy is being used efficiently," Mr

Eddie Wu, Energy Services Manager of CLP Power Hong Kong said. "You can always find room

for improving energy efficiency. Just walk around your office or premises and perform a site

survey following the Energy Audit Guidelines, which is available from various sources such as

the Government's Website."

Since 1999, CLP has dedicated an Energy Services Team to conduct energy

audits for more than 500 large commercial and industrial customers, helping them increase

energy efficiency and achieve tangible energy savings. Amongst them is a large property

management company which manages many office towers, hotels, service apartments and shopping

arcades, a case illustrated by Mr Wu.

"On lighting and hot water supplies, a customer installed over

20,000 electronic ballasts, phased out several aging gas or diesel boilers and switched to the

highly energy efficient and emissions-free heat pump water heating systems. On power supply,

capacitor banks have been installed to improve the power factor. On air-conditioning, the

customer was advised to use fresh water cooling towers for chiller heat rejection. Total

energy savings from all these initiatives is as high as 5 GWh a year."

An energy audit is similar to financial accounting. It is a quick way to

assess and analyze energy performance, identify obvious energy wastage and opportunities for

energy savings that help reduce emissions.

"Through auditing, customers are made aware of their potential areas

of energy inefficiency," Mr Wu continued to explain. "During the visits to

customers' premises, we gave various advice to clients, ranging from housekeeping management

to installation of energy-efficient equipment. Our experience shows that through an energy

audit most users can identify the potential to save 5-10% on overall energy costs."

Many energy saving practices are just simple steps. For example,

replacing T12 or T10 fluorescent tubes with T8 or T5 energy efficient fluorescent tubes can

improve energy efficiency by 10% to 30%. Using LCD monitors can save more than 50% off

electricity usage compared to CRT monitors. Regular cleaning of condenser tubes, cooling coils

and air filters can help maintain cooling efficiency. Purchasing energy efficient equipment

can reduce the level of energy consumption, etc.

CLP Power has actively contributed to raising energy saving and

environmental awareness through various programmes such as energy audits, community-based

education programmes and regular seminars/conferences to exchange international and local

energy practices with SMEs. |

|

Download this Chapter (In PDF Format) Download this Chapter (In PDF Format)

|